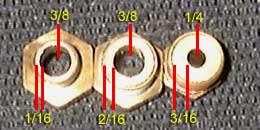

To be able to lift the car quickly, you need to enlarge the diameter of the hole where the airline connects. Simply attaching a bigger line will not make the system faster. Below is a comparison between the stock size and the enlarged size as well as the stock configuration and modified strut with airline attached. Using a hacksaw, I was able to hack off the stock solenoid mounting bracket and drill a 5/16" hole in the leftover material. Next I bought a 1/8" NPT tap and threaded the hole to accept an1/8" NPT fitting. I also drilled a 7/16" hole in the body of the strut and tapped it to accept a 1/4" NPT fitting.

The finished strut uses a 1/2" suppy line and a 3/8" dump line. You can click the leftmost pic for a close up. Depending on where you drill on the base of the strut and what fittings you decide to use, you may or may not have clearance problems when you install the strut. The fittings are located towards the engine compartment which could make it difficult to install the lines once the strut is in place. The other option is to cap the stock solenoid hole and drill the new holes on the outermost side of the strut (away from the engine compartment). You have to take into consideration the travel of the control arm/steering knuckle if you do so.

The other problem I ran into was that the fitting would not screw in because part of the strut was in the way. To solve this, I ground down a portion of the strut, then finally switched to a different fitting. Some fittings will swivel which will allow you to screw in a 90 degree elbow in a tight spot. These are the fittings that may be a tight fit since they protrude more than the others.

REAR BAGS:

The rear was similar to the fronts except they were much easier. I didn't even have to remove the bags from the car. I used the same drill bit (7/16") and drilled directly into the plastic mounting base of the bag. If you are using a 90 degree fitting like the one pictured, make sure you have enough clearance to thread the fitting into the bag, there is a plate that the body of the fittings will hit if you drill the hole too close to the top of the bag. You can also use different fittings which swivel. I didn't find these until later. I kept the stock solenoid mounted in place and I have not yet had a problem with the rear bags leaking.

A picture of the 3/8" hose leading to the rear airbag. The stock solenoid can be left in place.

LEFT:

Just in case you decide you want maximum speed, you have the option of drilling multiple holes in the bags or larger holes altogether (see below)

BELOW:

The first two pictures show the front struts threaded to accept 1/4" fittings and 1/2" line instead of the miniture 1/8" fittings. If speed is what you need, you can run two 1/2" valves and Nitrogen. The next two pictures show what I tried to do to get an additional inch of lowering out of the front struts. I made the hole too high and it didn't work out as you can see from the pics. I estimate a 1/2" drop would be possible.